Review Article3: Algal Oil Production

1. Introduction

In September 2015, the United Nations adopted the Sustainable Development Goals (SDGs) during its summit, with "GOAL13: Take Urgent Action to Combat Climate Change and its Impacts" being a prominent objective. In December of the same year, the Paris Agreement was established during the United Nations Framework Convention on Climate Change (COP), outlining the international framework for addressing climate change beyond 2020. Under this agreement, Japan committed to reducing its greenhouse gas emissions, primarily CO2, by 26% compared to 2013 levels by the year 2030.

Simultaneously, the International Civil Aviation Organization (ICAO), of which Japan is a member, reached an agreement at its 2016 General Assembly to cap post-2020 CO2 emissions. To achieve this goal, Asian countries such as Singapore, Thailand, China, and India, along with the United States, major EU nations, Canada, Australia, are considering the introduction of biojet fuels. This effort necessitates the production of lipids, which serve as a key feedstock for jet fuel.

2. Euglena's Oil Production Concept

Euglena, scientifically known as Euglena, is a single-celled microalgae that produces nutrition through photosynthesis. Under oxygen-deprived conditions, Euglena is known to convert carbohydrates within its cells into wax esters, accumulating them. These wax esters can be converted into biofuels through processes like ester bond cleavage, making them a valuable resource. Euglena-derived oil is not only promising for bioenergy but also finds applications in cosmetics, food, pharmaceuticals, and more.

Since the 1990s, research has been ongoing to utilize Euglena for the advanced utilization of carbon dioxide. However, the societal implementation of large-scale production faced challenges primarily due to the relatively high costs associated with valuable compounds derived from microalgae compared to common commodities. Nevertheless, the current market conditions show that biofuels are traded at prices higher than fossil fuels, and there is growing support for environmentally friendly products in various countries and markets. In such a context, microalgae-derived components play a significant role as environmentally conscious materials. Table 1 illustrates examples of Euglena utilization based on the 5Fs of biomass (Food, Fiber, Feed, Fertilizer, Fuel).

| Category | Euglena's Features and Industrial Advantage | Practical Applications |

|---|---|---|

| Food | Immunomodulatory functions of Paramylon (β-1,3-glucan), a variety of nutrients including unsaturated fatty acids and B-vitamins | Food products (drinks, supplements, general food items), Cosmetics (skincare products, etc.) |

| Fiber | High functionality due to the processing characteristics and biocompatibility of Paramylon's β-1,3-glucan structure | Organic fillers for PP compounds, Rayon, ABS-like resins with derivatization |

| Feed | Improved feed conversion rates, enhanced quality, and brand positioning, reduced methane emissions | Feed for domestic chickens, initial feed for aquaculture, land-based aquaculture |

| Fertilizer | Activation of soil microorganisms, improved moisture retention in crops, increased antioxidant levels in crops | Compost, potting soil, liquid fertilizer, biostimulants |

| Fuel | Lightweight fuel based on wax esters, low carbon chain lengths (C14) | Solid fuels, liquid fuels (diesel, jet fuel) |

In a bio-refinery process, the production of multiple products from a single process is possible, emphasizing the importance of considering the use of residues alongside the development of high-value products. For example, in the case of biofuels, the residues left after oil extraction can be utilized as feed or fertilizer. This approach minimizes waste and enhances the overall process efficiency.

3. Introduction to Research and Development for Enhanced Productivity

Research on Euglena-based oil production productivity, which can be conducted within a laboratory setting, focuses on breeding strains suitable for oil production and investigating cultivation conditions. This section introduces research on strain selection.

3.1 Collection of Euglena from Natural Environments

Euglena exists widely in natural environments, with numerous species identified. Among them, Euglena gracilis stands out as it can efficiently multiply and possesses high environmental adaptability. The "Minna no Midorimushi Project," initiated in 2019, involved the collection of various traits-bearing Euglena (referred to as "novel trait strains") from lakes and ponds across Japan by high school students and their families. Analysis of Euglena's ITS2 DNA sequences revealed 19 different Euglena strains, along with the discovery of seven new ITS2 sequences (Table 2). Research is ongoing regarding the industrial potential of these novel trait strains. With over a thousand samples collected to date, a phylogenetic tree has been constructed, and the assessment of each strain's potential for industrial use is underway.

| Fiscal Year | Number of Samples | Samples with Euglena | Strains Established | Number of ITS2 Types | New ITS2 Types |

|---|---|---|---|---|---|

| 2019 | 207 | 14 | 13 | 5 | 1 |

| 2020 | 295 | 31 | 34 | 15 | 6 |

| 2021 | 543 | 33 | 33 | 12 | 2 |

| Duplicate | 13 | 2 | |||

| Total | 1045 | 78 | 80 | 19 | 7 |

3.2 Breeding via Random Mutation

Euglena was known to exhibit resistance to DNA mutations. Still, by employing heavy-ion beam irradiation capable of inducing dynamic mutations, a population of cells with distinct characteristics was created. From these cell populations, a method was developed to select specific cells using cell sorters. Euglena mutants with significantly higher lipid content produced using this method.

This method, which visually identifies lipids through BODIPY staining, allowed the selection of Euglena cells with higher lipid content compared to wild strains by approximately 40%.

3.3 Utilization of Genome Editing Techniques

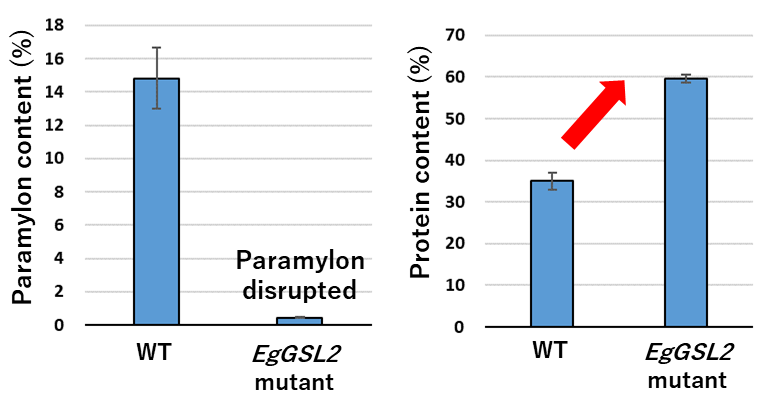

From a resource circulation perspective in industry, it is essential to enhance the productivity of microalgae during cultivation. To achieve greater productivity, strain improvement is necessary. Euglena is reported to be highly amenable to genome editing compared to other microalgae. The first genome editing achievement involved rendering the EgGSL2 gene, which is associated with paralytic biosynthesis in Euglena, non-functional through genome editing, resulting in a paralytic-deficient strain (Figure 1). This paralytic-deficient strain contains approximately 1.7 times more protein than the wild strain and holds promise for protein production. In the future, genome editing techniques can be utilized to efficiently produce various organic resources highly demanded in markets, including lipids. Additionally, genes related to flagella formation essential for swimming were rendered non-functional, creating Euglena strains incapable of swimming. These strains possess the characteristic of precipitating the algal body by merely allowing the culture solution to stand. This suggests that there is potential to impart distinctive features to biomass productivity itself.

4. Efforts for Societal Implementation

The author's affiliated company, Euglena Co., is engaged in the production of Euglena and Chlorella for food purposes in Ishigaki City, Okinawa Prefecture. Recently, the company has been conducting various cultivation experiments with the premise of scaling up using various component technologies to develop business schemes that address new societal challenges, aiming for societal implementation. Below, we introduce the details of these efforts.

4.1 Demonstration for Biofuel Production

The combustion of fossil fuels is considered the largest contributor to carbon dioxide emissions, which have a significant impact on global warming, accounting for 77% of total greenhouse gas emissions. There is a global movement to reduce greenhouse gas emissions, and the Paris Agreement in 2016 has strengthened low-carbon policies in various countries. In Japan, carbon recycling targets have been set for various sectors, including chemicals, fuels, and minerals. Among these, microalgae biofuels are gaining attention as promising candidates for liquid fuels. Microalgae have higher fuel yield per unit land area than plants, do not compete with food production, and have the potential to address issues such as tropical rainforest destruction, making them a solution to traditional biomass material challenges.

As raw materials for biofuels, waste oils such as palm-based waste oil, waste cooking oil, and animal fats are also considered in addition to microalgae-derived oil. The estimated global stockpile of waste oils is approximately 310-420 million tons per year as of 2030. However, these waste oils alone are insufficient to meet the demand for biojet fuel, which is estimated to require approximately 500 million kL by 2050. Therefore, there is a need to efficiently and stably produce large quantities of lipids derived from microalgae for use as fuel raw materials.

To maximize the growth potential of microalgae, it is important to cultivate them in optimal conditions for each microalgal species. Productivity is limited by photosynthesis rates, so regions with high solar radiation and stable water temperatures throughout the year are desirable. Regions near the equator are potential candidates for high-temperature and high-radiation cultivation. Euglena Co. has isolated strains from lakes in Fukushima Prefecture with higher temperature resistance than conventional Euglena strains. These strains have a reduced decrease in growth rate even at water temperatures exceeding 32°C, and the average growth rate at the optimal temperature of around 29°C is approximately 1.5 times that of conventional strains. Acquiring this high-temperature-resistant strain has opened the possibility of stable cultivation near the equator. At the same time, site selection is also progressing. To date, cultivation trials with small-scale cultivation tanks have been conducted in Indonesia and Colombia. These trials estimated an average annual growth rate about 1.4 times higher compared to Japan.

Furthermore, the company is improving the production process, including exploring microalgal strains and developing new drying methods using waste heat, to accelerate research and development for commercial production.

In Japan, Euglena Co. has established a demonstration facility for microalgae production in Taki-cho, Mie Prefecture, adjacent to the Chubu Plant Services thermal power plant. With the use of this facility, the company has been verifying whether it can achieve productivity that is acceptable in terms of cost, energy balance, and material balance with the cooperation of local governments, companies, and research institutions. Specifically, a 1,000 m² cultivation system has been installed to confirm biomass productivity throughout the year, and studies on energy-efficient biomass drying processes and lipid extraction from biomass have been conducted (Figure 2).

The company is also studying the utilization of the high-protein residue remaining after extracting lipids from microalgae. Analysis of the amino acid composition of this residue has shown a composition highly similar to fishmeal. Therefore, this residue is expected to be an alternative to fishmeal. Additionally, Euglena Co.'s lipid extraction method from microalgae selectively extracts neutral lipids, leaving polar lipids in the residue, making it suitable for animal feed.

The global demand for seafood has been increasing due to population growth. The supply of edible seafood has increased approximately 4.5 times in the 50 years from 1960 to 2010, reaching 1.23 million tons. However, the catch of natural edible seafood has remained stable at around 900,000 tons per year since 1990, indicating its limitations. Therefore, meeting the increased demand for edible seafood relies on aquaculture production. However, the primary source of protein for aquaculture feed, fishmeal, is mainly derived from anchovies, and there are limits to the catch volume. To increase aquaculture production, alternative raw materials are needed. Thus, utilizing by-products as feed ingredients is socially important.

In Taki-cho, the potential for branding feed using algae is being explored, and the development of "Taki Brand Feed" using local unused resources and Euglena is progressing. Additionally, test marketing of "Taki Sustainable Salmon" has been conducted (Figure 3). In the future, the company plans to continue verification trials for the business model of co-producing biofuel lipids and feed protein materials.

4.2 Demonstration for Biofuel Refinement

Amid the global proliferation of biofuels, Euglena Co. initiated the "Domestic Biofuel Plan" on December 1, 2015, in collaboration with the City of Yokohama, Chiyoda Chemical Engineering & Construction Co., Ltd., Itochu Enex Co., Isuzu Motors Ltd., and ANA Holdings Inc., aiming to practicalize domestically produced biojet and diesel fuels. Construction of Japan's first biojet and diesel fuel demonstration plant began on June 1, 2017, and was completed in 2018. Since spring 2019, the plant has been in full operation, producing biofuels from used cooking oil and Euglena powder, among other raw materials.

The plant is located in Tsurumi Ward, Yokohama City, Kanagawa Prefecture, with a site area of 7,787.6 square meters. It has a daily production capacity of five barrels and an annual production volume of 125 kL (subject to variation depending on test implementation and maintenance). The product range includes biojet fuel, next-generation biodiesel fuel, and bio-naphtha, among others. The production technology is based on the Biofuels ISOCONVERSION Process (BIC Process) licensed from Chevron Lummus Global/ARA. The total investment cost is approximately 5.8 billion yen, including subsidies from Kanagawa Prefecture and Yokohama City.

5. Conclusion

To achieve a sustainable society, it is crucial to realize carbon-centered material circulation, and microalgae, which play a role in primary production, are considered essential. The company has focused on research and development to establish a business model centered on microalgae biorefinery, with the goal of contributing to the realization of a sustainable society. By utilizing various types of microalgae, the company is developing highly efficient methods for material production. Furthermore, the company is studying the improvement of microalgae cultivation methods using untapped resources such as urine and organic waste recycling liquid