Review Article2: Algal Bio-Refinery

1. Introduction

The Sustainable Development Goals (SDGs), adopted at the United Nations Summit in 2015, represent a globally shared agenda to achieve a sustainable future for all nations. To attain these SDGs, the utilization of renewable biological resources becomes imperative.

In recent years, a concept gaining prominence as a means to achieve SDGs involves the idea of a biorefinery based on cultivated microalgae, aiming to produce renewable resources. A biorefinery refers to the technology and industry that utilizes biomass as a raw material to produce biofuels, chemical feedstocks, and more. This article focuses on the concept of a biorefinery, rooted in the current landscape of algae-related initiatives, and presents examples of our efforts.

2. A Novel Biorefinery Process Concept

Microalgae, through photosynthesis, harness solar energy to convert carbon dioxide and water into organic matter and oxygen, thereby producing valuable substances for human use. Their high carbon dioxide fixation capability has led to the notion of producing them in proximity to carbon dioxide-emitting sources, such as power plants.

Efforts to harness carbon dioxide for advanced utilization have been ongoing since the 1990s. However, practical implementation has been limited due to the challenge of demonstrating cost competitiveness for valuable substances derived from microalgae compared to widely available commodities. Nevertheless, the current market dynamics, where biofuels are traded at prices higher than fossil fuels, and the growing willingness of countries and markets to purchase environmentally conscious products, are changing the game. Therefore, supplying algae-derived components as environmentally friendly materials to existing markets becomes increasingly crucial.

| Category | Euglena's Features and Industrial Advantage | Practical Applications |

|---|---|---|

| Food | Immunomodulatory functions of Paramylon (β-1,3-glucan), a variety of nutrients including unsaturated fatty acids and B-vitamins | Food products (drinks, supplements, general food items), Cosmetics (skincare products, etc.) |

| Fiber | High functionality due to the processing characteristics and biocompatibility of Paramylon's β-1,3-glucan structure | Organic fillers for PP compounds, Rayon, ABS-like resins with derivatization |

| Feed | Improved feed conversion rates, enhanced quality, and brand positioning, reduced methane emissions | Feed for domestic chickens, initial feed for aquaculture, land-based aquaculture |

| Fertilizer | Activation of soil microorganisms, improved moisture retention in crops, increased antioxidant levels in crops | Compost, potting soil, liquid fertilizer, biostimulants |

| Fuel | Lightweight fuel based on wax esters, low carbon chain lengths (C14) | Solid fuels, liquid fuels (diesel, jet fuel) |

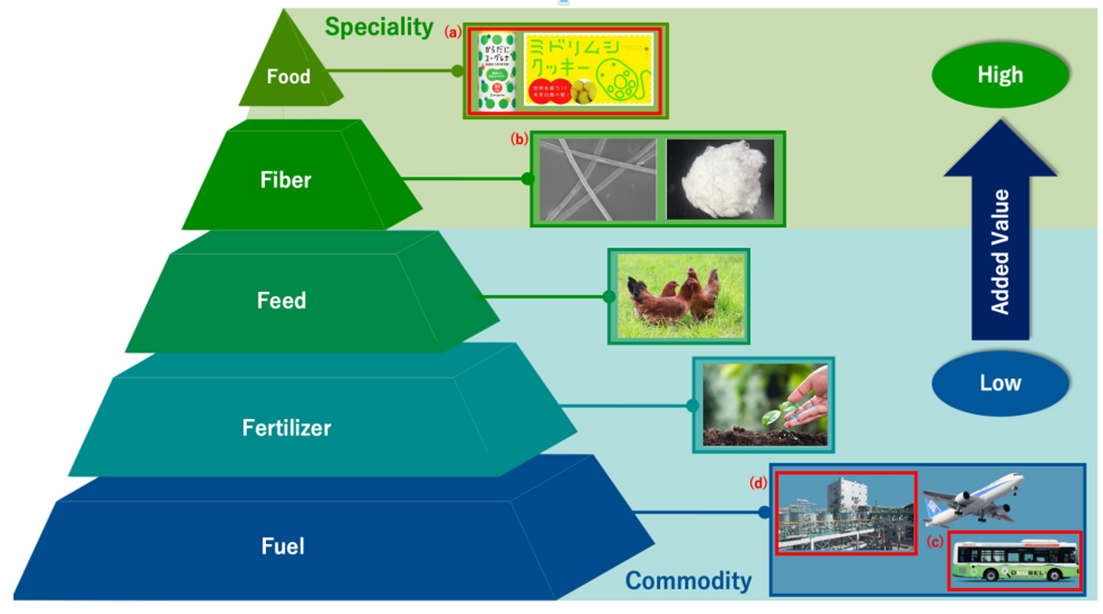

2.1 Multiple Utilization Based on the 5Fs of Biomass

In fields like forestry engineering, a fundamental principle known as the "5Fs of Biomass" is applied. This concept arranges the five uses of biomass – Food, Fiber, Feed, Fertilizer, and Fuel – in order of their high-value addition in biomass utilization. Products at higher positions command relatively higher prices. For example, "Food" at the top position, being high in unit value, can further increase the unit price when marketing strategies and supply methods are strategically employed. Conversely, chemical products and fuels used in other biorefinery processes tend to have lower market prices as commodities. For instance, fossil fuels have lower market prices per unit weight compared to other commodities and materials. To achieve cost-competitive supply, low-cost production is necessary. However, recent incentives for using biofuels, even at prices higher than market prices, to comply with regulations in various countries have made the multi-stage utilization of the 5Fs of biomass more favorable. Table 1 demonstrates the potential uses of microalgae, specifically Euglena, based on the 5Fs of biomass.

Multiple products can be produced from a single biorefinery process, emphasizing the importance of designing high-value products and exploring the utilization of residues. For example, in the case of biofuels, the residue remaining after oil extraction is aimed to be utilized as feed or fertilizer.

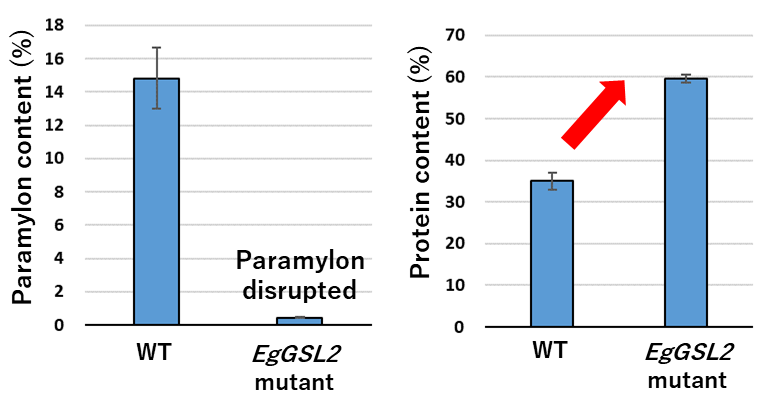

2.2 Leveraging Genome Editing Technology

From the perspective of resource circulation in the industrial sector, proper genetic improvement is necessary to increase productivity in microalgae cultivation. Euglena, in particular, has reported high-efficiency genome editing capabilities compared to other microalgae, opening the door for genetic improvement (1). As an initial case of genome editing, they have created a mutant strain lacking the EgGSL2 gene, one of the genes related to Paramylon biosynthesis in Euglena, rendering it non-functional (Figure 1). This Paramylon-deficient strain contains 1.7 times more protein content than the wild strain and is expected to be suitable for protein production. In the future, the efficient production of various organic resources in high demand in the market, including lipids, carbohydrates, and proteins, could be achieved through the application of genome editing. Additionally, they have successfully created strains with reduced motility through genome editing, providing an advantage in harvesting (2). Hence, there is potential to impart unique characteristics to biomass production itself.

3. Initiatives for Societal Implementation

Euglena Co., Ltd., a company specializing in microalgae cultivation, is actively involved in developing innovative solutions to address pressing societal challenges. With a focus on scalability and social implementation, the company is conducting various cultivation experiments utilizing core technological elements. This article provides an insight into these initiatives.

3.1 Biofuel Production

The impact of global warming is primarily attributed to the emission of carbon dioxide (CO2) resulting from the combustion of fossil fuels, which accounts for 77% of total greenhouse gas emissions. This has led to increased efforts worldwide to reduce greenhouse gas emissions, particularly after the Paris Agreement came into effect in 2016. Japan has set targets for carbon recycling in various sectors, including chemicals, fuels, and minerals. Microalgae-based biofuels, particularly those derived from microalgae lipids, have gained attention as a potential candidate for liquid fuels due to their high yield per unit land area, non-competition with food crops, and lack of tropical forest destruction associated with traditional biomass materials.

In addition to microalgae-derived oils, waste oils like used cooking oil, palm-based waste oils, and animal fats are considered potential feedstocks for biofuels. However, the estimated global availability of waste oil-based feedstocks is insufficient to meet the demand for bio-jet fuels estimated to be approximately 500 million kL by 2050. Therefore, it is essential to efficiently and stably produce large quantities of lipids from microalgae as a fuel source.

To maximize the growth potential of microalgae, it is crucial to cultivate them in the optimal environmental conditions for each microalgal species. Since the productivity per unit area is limited by photosynthesis rates, regions with high solar radiation and stable water temperatures throughout the year are preferred for cultivation. Areas near the equator are considered suitable for high-temperature cultivation. Euglena Co., Ltd. has isolated strains of microalgae with high-temperature tolerance from lakes in Fukushima Prefecture, Japan, surpassing conventional Euglena (Euglena gracilis) strains in terms of high-temperature resistance. These strains exhibit less reduction in growth rates at temperatures above 32°C and approximately 1.5 times higher average growth rates at around 29°C compared to conventional strains. This breakthrough in high-temperature-tolerant strains has paved the way for stable cultivation near the equator. Site selection is also progressing. Trials conducted in Indonesia and Colombia have revealed approximately 1.4 times higher growth rates in overseas locations compared to the annual average growth rates in Japan. The company is also working on improving production processes, including the exploration of microalgae strains and novel drying methods using waste heat, to accelerate research and development for commercial production.

In Japan, Euglena Co., Ltd. has established a demonstration facility for microalgae cultivation in Taki Town, Mie Prefecture, adjacent to Chubu Plant Service Co., Ltd.'s thermal power plant. This facility aims to verify the productivity that is acceptable in terms of cost, energy balance, and material balance in the market. The specific testing involves installing 1,000 square meters of cultivation equipment to confirm biomass productivity throughout the year and conducting studies on highly efficient biomass drying processes and lipid extraction from biomass.

Furthermore, the company is exploring the utilization of the high-protein residue remaining after lipid extraction, which closely resembles fishmeal in terms of amino acid composition. This residue has the potential to be a suitable ingredient for livestock and aquaculture feed due to its desirable lipid characteristics. With the world's population increasing and a growing demand for edible fish and seafood, aquaculture is expected to play a significant role in meeting this demand. However, the primary protein source in aquaculture feeds, fishmeal derived from anchovies, has limitations in terms of availability. Therefore, utilizing byproducts as feed ingredients holds great societal significance. In Taki Town, the company is working on the development of "Taki Brand Feed" using local unused resources and microalgae Euglena to verify the potential of feed and test the distribution of "Taki Sustainable Salmon" in the market.

3.2 Resource Circulation for Local Communities

Euglena Co., Ltd. aims to utilize nitrogen, phosphorus, and CO2 while absorbing CO2 through photosynthesis. To achieve this goal, the company established the Saga Sustainable Tech Farm near the Saga City sewage treatment center. This farm conducts research on liquid fertilizers and cultivation soil, utilizing cultivated microalgae biomass, with the aim of realizing resource-circulating agriculture. The process involves cultivating microalgae Euglena using resources from sewage treatment plants and producing fertilizers from the biomass. These fertilizers are then utilized for the growth of local crops, contributing to both resource circulation and regional development.

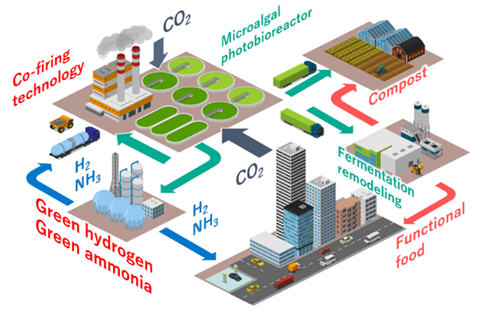

Moreover, the company is collaborating with Japanese research institutions and local organizations to develop a carbon recycling system using microalgae in Indonesia, focusing on four key areas: (1) installing microalgae photobioreactors at major CO2 emission sources, (2) developing CO2 capture technology through microalgae genome breeding, (3) producing new fermented foods and compost through microalgae-based fermentation remodeling, and (4) advancing the production of hydrogen-based fuels from biomass and coal by using chemical looping and reducing carbon emissions from coal-fired power generation. The company is working on research and development to provide policy proposals based on these findings, in collaboration with research institutions, power generation and renewable energy companies, and government agencies in partner countries, with the aim of achieving societal implementation.

Within these initiatives, research and development related to fermentation remodeling have already commenced. The company has developed "Green Tempe," a high-value product that improves taste and nutrient content, by adding Euglena powder during the fermentation process of traditional Indonesian tempe. Analysis of Green Tempe has shown an increase in ergothioneine content, an antioxidant that cannot be synthesized in the human body, by approximately 1.7 times compared to conventional tempe. In addition to enhancing the nutritional value, Green Tempe also offers improved sensory qualities, with a smoother texture and enhanced umami taste, making it more appealing to consumers.

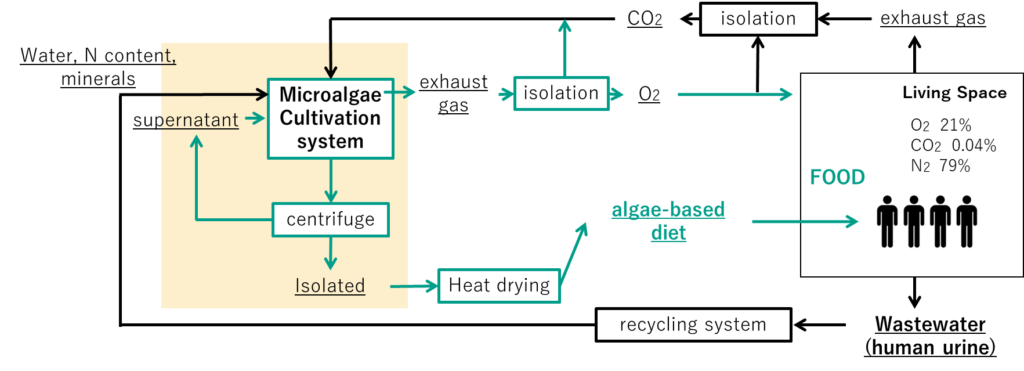

3.3 Material Production in Space

The application of microalgae extends beyond Earth. Euglena Co., Ltd. is actively engaged in research on the production of materials in space. The unique capabilities of microalgae, such as rapid growth and photosynthesis, make them suitable candidates for space cultivation. Microalgae can absorb CO2 and release oxygen through photosynthesis, making them valuable components for life support systems in space. Euglena has conducted experiments on the International Space Station (ISS) and initiated a project to produce a resource circulation system by cultivating Euglena in space and converting it into food and oxygen.

These initiatives represent Euglena Co., Ltd.'s commitment to addressing global challenges through innovative approaches. Whether it's producing sustainable biofuels, creating resource-circulating agriculture, or exploring material production in space, the company's work is driven by a vision of a more sustainable and interconnected world.

4. Conclusion

Euglena Co., Ltd.'s endeavors in microalgae cultivation exemplify the potential for nature-based solutions to tackle pressing societal challenges. By harnessing the unique properties of microalgae, such as their high-temperature tolerance, carbon sequestration capabilities, and rapid growth, the company is contributing to the development of sustainable biofuels, resource-circulating agriculture, and material production in space. These initiatives underscore the importance of interdisciplinary collaboration and innovation in addressing complex global issues. As Euglena continues to expand its research and implementation efforts, the possibilities for microalgae-based solutions in a changing world are boundless.