Cell growth of microalgae Euglena in a 3D bioprinted structure

Euglena Co., Ltd. has confirmed that microalgae Euglena cells used as bioink material for 3D bioprinting have grown inside the 3D printed structure in a joint research project with RIKEN, Hiroshima University, and Nagasaki University, Faculty of Information and Data Science. The research paper is based on a 3D image. This research paper was selected as an outstanding paper at the 3D Image Conference 2022 (http://www.3d-conf.org/).

Background and Purpose of Research

3D printing technology, which is widely used in industry, has been applied in the field of bioprinting using biomaterials because it can print living cells in the desired structure (shape), and in recent years, research has been conducted mainly in the field of regenerative medicine using animal cells.

On the other hand, 3D bioprinting in the plant field is expected to be applied to improve the efficiency of plant growth time and location by printing edible parts of plants, such as grains and fruits, for example.

The rough steps of 3D bioprinting include the following three steps.

- Search for appropriate bioink materials (cells to be used, gels suitable for the cells and the conditions of the 3D printer, etc.)

- Printing the structure with a 3D printer

- Cultivation of the printed structures (cell growth)

The conditions for cells to be used in 3D bioprinting bioink are that the cells must be above a certain number and cultured in the special environment of the 3D bioprinted structure, so the establishment of culture technology is a useful condition. Euglena does not require the process of isolating cells from plant bodies, which is necessary when culturing plant cells, because it does not have cell walls like animal cells, in addition to the established culture technology.

This time, assuming that euglena is suitable as a bioink material for 3D bioprinting, we printed structures and verified cell growth.

■ Research Methodology

1) Search for appropriate 3D bioprinting bioink materials

A mixture of a polymer or other gel and cells is used in 3D bioprinting as bioink. In this research, the following two types of bioink were prepared by using sodium alginate3 as a base and adding methylcellulose4 and other materials to strengthen the structure during printing.

A: Euglena cells mixed with 2 x 105 cells/ml of gel dissolved at a concentration of 3% sodium alginate solution and 9% methylcellulose

B: Euglena cells mixed with 2 × 105 cells/ml of gel dissolved in a concentration of 2% sodium alginate solution, 25% nonionic surfactant (Pluronic-F127)

2) Printing structures with 3D bio-printing

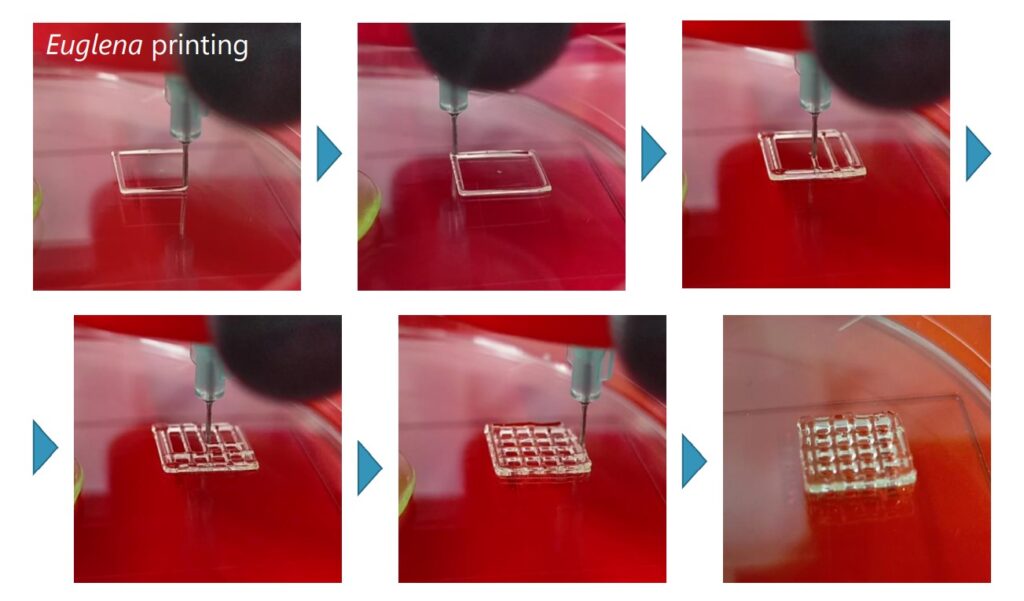

A 10mm x 10mm grid-like structure was printed with two types of bioink, A and B. The structure was then gelatinized in 100mM calcium chloride solution for 10 minutes (Figure 1).

(3) Cultivation of cells in 3D printed structures

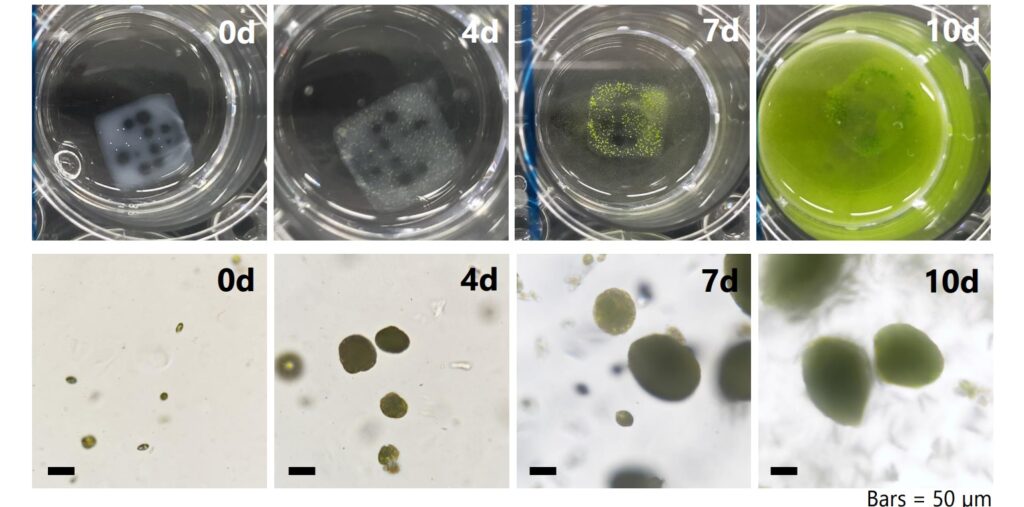

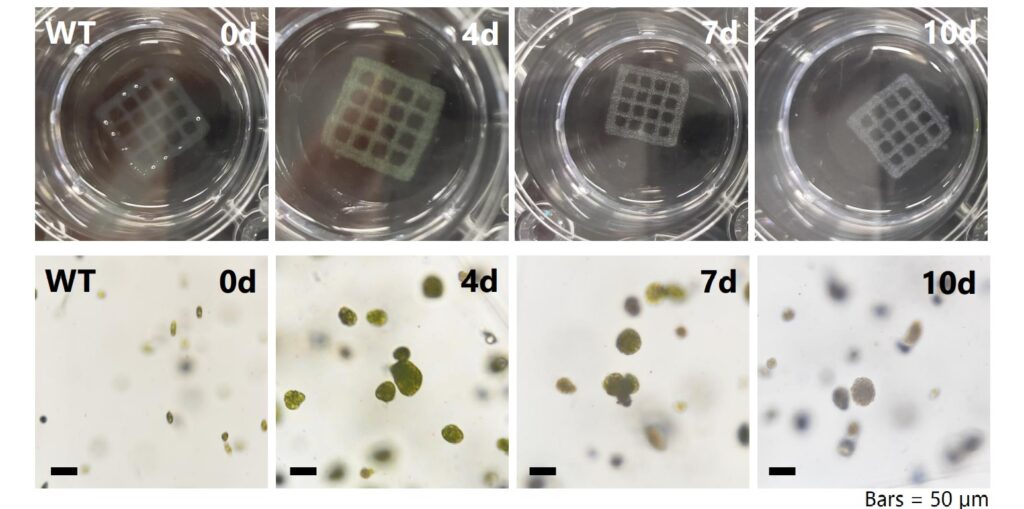

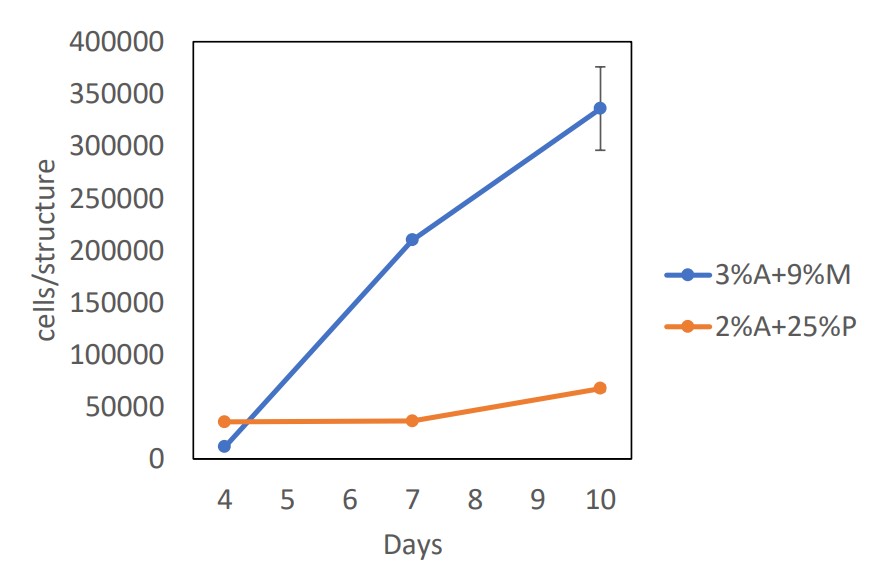

In order to examine whether Euglena cells are viable in the process from printing to culture in 3D bioprinting, each gelatinized structure was placed in a culture medium (pH 3.5) and cell changes were observed. We also dissolved the structures on days 4, 7, and 10 after culture and measured the number of cells (Figures 2 and 3).

(iv) Results

In the Bioink B structure, cells turned white and did not proliferate from day 7 of culture, whereas in the Bioink A structure, good cell proliferation was observed (Fig. 4). In addition, cell viability of Bioink A cells at day 7 of culture was similar to that of cells cultured in liquid medium. These results indicate that Bioink A is appropriate for culturing Euglena cells in 3D bioprinting.

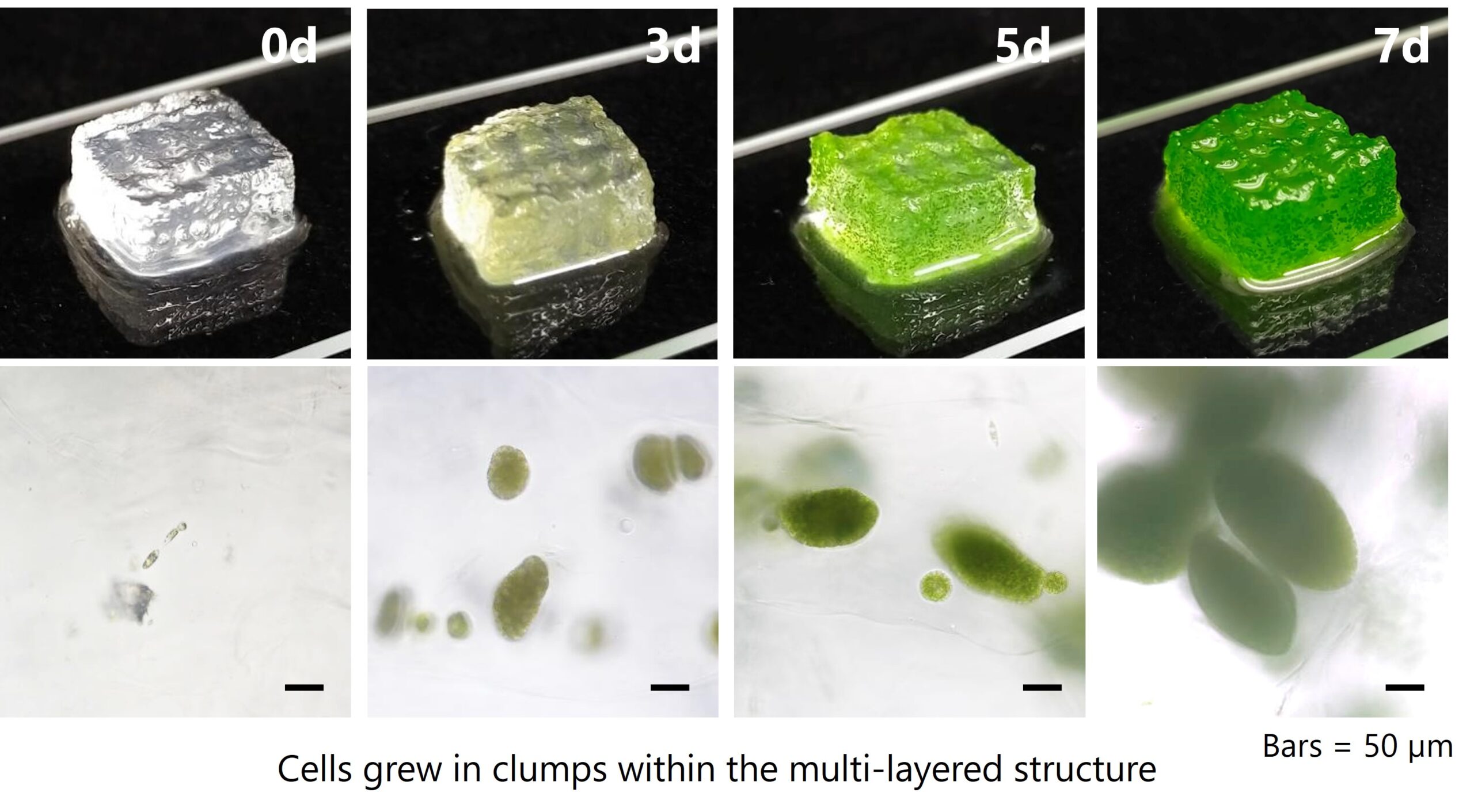

Furthermore, a 5 mm high lattice-like structure was also printed with Bioink A. The structure was gelatinized with 100 mM calcium chloride solution for 15 minutes and incubated in culture medium (pH 3.5) for 7 days, and the entire structure turned green, the color of Euglena cells. Observation of the inside of the structure with an optical microscope confirmed the growth of Euglena cells, indicating that Euglena cells can be cultured even in a more three-dimensional structure.

Based on the results of this verification, the possibility of application to various plant cells, including other microalgae, as a material for 3D bioprinting in the plant field is expected. In addition, we can expect the development of new cultivation methods for euglena, which is attracting attention as a material that can contribute to solving food problems and climate change, as well as its application in other fields, as its industrial use in the healthcare and energy fields is progressing. In order to realize a sustainable society, we are engaged in the healthcare business, biofuel business, and social business by utilizing microalgae such as Euglena. We will continue to promote research on various cultivation methods to expand the use of microalgae as a technology that contributes to solving social issues.